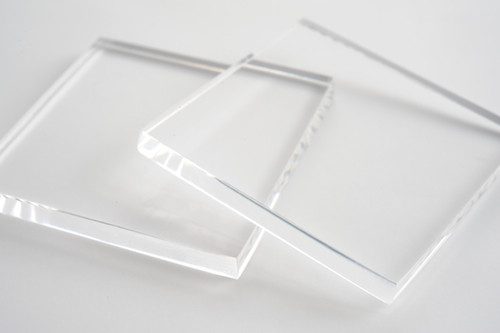

A sustainable alternative to plexiglass refers to a material that can be used as a substitute for traditional plexiglass while minimizing its negative environmental impact. Plexiglass, also known as acrylic glass, is widely used in various industries due to its transparency, durability, and versatility.

One example of a sustainable alternative to plexiglass is recycled acrylic. It is produced by reprocessing post-consumer or post-industrial acrylic waste, such as discarded signage, displays, or windows. This process reduces the demand for virgin materials and diverts waste from landfills. Recycled acrylic retains many of the properties of traditional plexiglass, offering clarity, impact resistance, and UV stability, while significantly reducing its environmental impact.

Why is finding a sustainable alternative to plexiglass important?

Finding a sustainable alternative to plexiglass is crucial due to several important reasons:

Plexiglass, or acrylic glass, is derived from non-renewable fossil fuels, contributing to carbon emissions and depleting finite resources.

Plexiglass production involves energy-intensive processes that contribute to greenhouse gas emissions and pollution. The manufacturing of sustainable alternatives focuses on reducing energy consumption, utilizing eco-friendly manufacturing techniques, and minimizing harmful emissions. This shift toward sustainability helps to address climate change and improve air and water quality.

Plexiglass waste poses a significant challenge. Traditional plexiglass is not easily recyclable and often ends up in landfills, where it can take hundreds of years to decompose. Sustainable alternatives offer improved end-of-life options, including recycling or biodegradation.

Finding a sustainable alternative to plexiglass is essential for minimizing our ecological footprint, combating climate change, and transitioning to a more sustainable and circular model of production and consumption.

What are the environmental concerns associated with plexiglass?

The production relies on the extraction and processing of non-renewable fossil fuels, such as petroleum or natural gas. This extraction process contributes to carbon emissions and further depletes finite resources, exacerbating climate change and resource scarcity.

Manufacturing of plexiglass involves energy-intensive processes that require significant amounts of electricity and water. The production facilities consume substantial energy, contributing to greenhouse gas emissions and straining local energy grids.

Traditional plexiglass is not easily recyclable due to its composition, and a significant amount of it ends up in landfills. Once in landfills, plexiglass can take hundreds of years to decompose, adding to the problem of plastic waste and its associated environmental impacts.

Are there any health concerns related to plexiglass?

Plexiglass, or acrylic glass, is generally considered safe for use, but there are a few health concerns that should be taken into consideration. One of the main concerns is the potential for exposure to airborne acrylic dust particles during cutting, drilling, or sanding processes.

Prolonged or excessive inhalation of these particles can irritate the respiratory system and cause respiratory distress or allergies. It is recommended to use appropriate personal protective equipment, such as masks, goggles, or respiratory protection when working with plexiglass to minimize the risk of inhalation.

Another health concern is the use of certain chemicals during the production or processing of plexiglass. These chemicals, such as solvents or adhesives, may emit volatile organic compounds (VOCs) into the air, which can contribute to poor indoor air quality and potential health effects, such as eye or respiratory irritation. Adequate ventilation should be provided in areas where plexiglass is being processed or installed to minimize exposure to VOCs.

Additionally, while plexiglass is generally considered a safe material, it can pose a risk of physical injury if it shatters or breaks under significant impact. Care should be taken to install plexiglass securely and use appropriate thicknesses or reinforcement techniques in high-risk areas to prevent accidental breakage.

It is important to follow proper safety guidelines, including handling, processing, and installing plexiglass, to minimize any potential health risks. Regular maintenance and cleaning of plexiglass surfaces can also contribute to maintaining a safe and healthy environment.

What are some common sustainable alternatives to plexiglass?

Several common sustainable alternatives to plexiglass have emerged as environmentally friendly alternatives. These materials offer comparable properties while minimizing environmental impact.

- Polycarbonate: Polycarbonate is a popular sustainable alternative to plexiglass. It is a durable and impact-resistant material that can withstand high levels of stress. It is commonly used in applications such as safety windows, protective barriers, and automotive components. Polycarbonate is also recyclable, allowing for a more sustainable end-of-life solution.

- Glass: Glass is a widely available and recyclable alternative to plexiglass. It offers excellent optical clarity and is resistant to scratching and yellowing. Glass can be used in various applications, including windows, displays, and architectural elements. Recycled glass is also increasingly used, which reduces the need for new glass production and conserves resources.

- Cellulose-based materials: Cellulose-based materials, such as cellulose acetate or cellulose propionate, are sustainable alternatives derived from renewable resources. These materials offer transparency, and good mechanical properties, and are biodegradable. They are commonly used in applications like sunglasses, eyeglass frames, and packaging.

How do sustainable alternatives to plexiglass compare in terms of durability?

Sustainable alternatives to plexiglass generally offer comparable or even improved durability compared to traditional plexiglass. These materials are engineered to be strong, impact-resistant, and long-lasting, making them suitable for a wide range of applications.

Bio-based polymers are also designed to offer durability. These materials can be formulated to possess high strength and impact resistance, ensuring their longevity in various applications. They can withstand everyday wear and tear, making them suitable for applications that require durability and reliability.

Sustainable alternatives are often engineered to have enhanced durability, including resistance to cracking, chipping, and discoloration. Additionally, manufacturers continuously improve the formulation and production processes of these materials to enhance their strength and performance, ensuring they meet or exceed the durability of traditional plexiglass.

Are sustainable alternatives to plexiglass more expensive?

Sustainable alternatives to plexiglass can vary in terms of cost, but they are not necessarily more expensive than traditional plexiglass. The cost of sustainable alternatives depends on factors such as the specific material, manufacturing processes, sourcing, and market demand.

Recycled acrylic, for instance, may be competitively priced or slightly higher in cost compared to traditional plexiglass. However, as the demand for sustainable materials increases and economies of scale are achieved, the price difference is likely to diminish over time. Additionally, the cost of recycled acrylic may be offset by potential savings in waste disposal fees or by aligning with sustainability goals.

Bio-based polymers, on the other hand, can have variable pricing depending on factors such as the type of bio-based material, availability of raw materials, and production methods. In some cases, bio-based polymers may have a higher upfront cost due to the use of renewable resources or more eco-friendly manufacturing processes. However, as technology advances and market adoption increases, the cost gap between bio-based polymers and traditional plexiglass is expected to narrow.

Can sustainable alternatives to plexiglass be recycled?

Sustainable alternatives to plexiglass can often be recycled, providing an environmentally friendly end-of-life solution. Recycling these materials helps to reduce waste, conserve resources, and minimize the environmental impact associated with traditional plexiglass.

Recycled acrylic, for example, can be recycled and reprocessed into new acrylic sheets or other products. This involves collecting post-consumer or post-industrial acrylic waste, breaking it down, and reforming it into new usable materials. By diverting acrylic waste from landfills and reintroducing it into the production cycle, the demand for virgin materials is reduced, leading to significant environmental benefits.

Similarly, some bio-based polymers are designed to be biodegradable or compostable, offering an alternative end-of-life option. These materials can break down naturally over time, reducing their environmental impact. However, it is important to follow proper recycling or disposal guidelines specific to each bio-based polymer to ensure it is processed correctly and does not end up in the wrong waste stream.

The recyclability of sustainable alternatives to plexiglass supports the principles of a circular economy by promoting the reuse and recycling of materials. It encourages a more sustainable approach to production and consumption while reducing waste and conserving valuable resources.

How do sustainable alternatives to plexiglass perform optically?

Sustainable alternatives to plexiglass are engineered to perform optically, providing clarity and transparency similar to traditional plexiglass. These materials undergo rigorous manufacturing processes to ensure excellent optical properties, allowing for clear visibility and light transmission.

Recycled acrylic, for example, maintains optical clarity comparable to traditional plexiglass. It offers high light transmittance, allowing for excellent visibility and minimal distortion. This makes it suitable for applications where visual clarity is essential, such as windows, displays, and signage.

Bio-based polymers also offer good optical performance. These materials are designed to have low haze and high light transmission, ensuring clear visibility through the material. They exhibit minimal color distortion and excellent light scattering properties, allowing for the transmission of light without compromising the material’s integrity.

Sustainable alternatives are continuously improving in terms of optical performance, with manufacturers striving to match or exceed the optical qualities of traditional plexiglass. While there may be slight variations in optical properties among different sustainable alternatives, they generally offer satisfactory clarity, making them suitable for a wide range of applications that require optical transparency.

Are there any specific industries or applications where sustainable alternatives to plexiglass are commonly used?

Sustainable alternatives to plexiglass find applications across a range of industries where transparency, durability, and environmental consciousness are key considerations. One such industry is architecture and construction.

Sustainable alternatives are used for windows, skylights, and facades, offering energy efficiency, weather resistance, and aesthetic appeal. These materials contribute to sustainable building practices by reducing the carbon footprint and promoting eco-friendly design.

Another industry where sustainable alternatives are commonly utilized is retail and signage. They are used for displays, shelving, and point-of-sale materials, providing both transparency and durability. Sustainable alternatives offer an attractive and eco-conscious solution for showcasing products and conveying brand messaging.

In the healthcare sector, sustainable alternatives are gaining popularity for applications such as protective barriers, medical equipment, and laboratory settings. These materials offer optical clarity, and impact resistance, and can be easily sanitized. Additionally, their eco-friendly properties align with the sustainability goals of healthcare facilities.

Are sustainable alternatives to plexiglass available in different colors and finishes?

Sustainable alternatives to plexiglass are available in a wide range of colors and finishes, offering versatility and customization options. Manufacturers of sustainable alternatives understand the importance of aesthetics and provide various options to meet the diverse needs of different applications and industries.

The availability of different colors and finishes in sustainable alternatives allows for creative freedom in design and helps these materials seamlessly integrate into various applications, such as architectural projects, signage, displays, and artistic installations.

Do sustainable alternatives to plexiglass require special maintenance or cleaning?

Sustainable alternatives to plexiglass generally do not require any special maintenance or cleaning compared to traditional plexiglass. However, it is important to follow basic care guidelines to ensure the longevity and optimal performance of these materials.

In terms of maintenance, sustainable alternatives can be cleaned using mild soap and water or non-abrasive cleaners. It is recommended to avoid harsh chemicals, abrasive cleaners, or rough scrubbing that could potentially scratch the surface. Regular cleaning with a soft cloth or sponge will help to remove dust, dirt, or fingerprints and maintain the transparency and appearance of the material.

Can sustainable alternatives to plexiglass be used for outdoor applications?

Sustainable alternatives to plexiglass can be used for outdoor applications. These alternatives are designed to withstand the rigors of outdoor environments, including exposure to sunlight, moisture, temperature fluctuations, and other environmental factors. They offer durability, weather resistance, and longevity comparable to or even better than traditional plexiglass.

How do sustainable alternatives to plexiglass handle temperature fluctuations?

Sustainable alternatives to plexiglass typically have good temperature resistance and can handle temperature fluctuations reasonably well. These materials are engineered to maintain their structural integrity and optical properties across a wide range of temperatures. They are designed to resist warping, cracking, or becoming brittle under extreme temperature conditions, ensuring their durability and reliability in various applications.

Leave a Reply